Electrical Contacts Types

Database contains categories for these types of electrical contacts

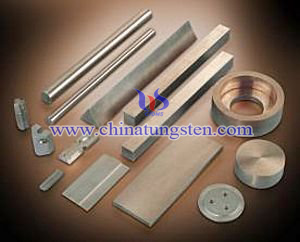

· EDM electrodes are used in electrical discharge machining (EDM), a process that removes metal with an electrical discharge of very short duration and high current density between the electrode and the workpiece.

· Welding electrodes are designed for resistance, arc, or plasma welding.

· Furnace electrodes are used to heat and melt metals or ceramics in arc furnaces. An arc is struck between the electrodes and furnace load material. The arc or plasma generates extremely high temperatures. The electrodes are commonly made from carbon-based materials.

· Electrical brushes are used in conjunction with slip rings and other contact surfaces to maintain an electrical connection in mobile or rotary applications. Graphite brush materials are used typically for high-power equipment. Metal brushes or sliding contacts are used for signal or low power applications.

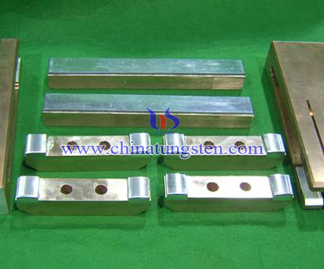

· Electrical contacts consist of a high-conductivity, soft, and oxidation-resistant material, often with a second phase to provide anti-welding and/or arc-resistance. They are used in circuit breakers, relays, switches, and EDM applications.

· Contact probes are contact or brush assemblies consisting of a contact with an integral spring that maintains sufficient contact force to assure low contact resistance. Contact probes and spring contacts typically have a plunger type configuration with an internal helical spring. Contact probes and spring contact are used in ATE test probe and battery contact applications.

· Battery contacts are designed for battery-contact applications. The contact often consists of a low-cost base metal such as steel or brass with a plated layer of high-conductivity or corrosion-resistant metal.