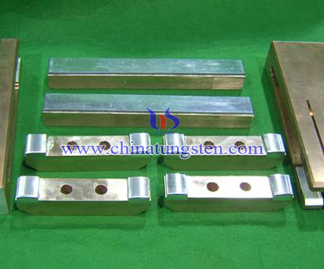

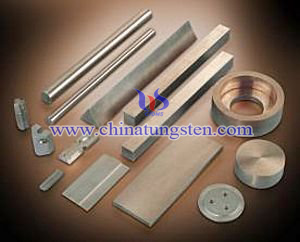

Tungsten Copper Electrical Contacts

Tungsten copper electrical contacts are subjected to extreme mechanical and thermal stresses during operation. For fractions of a second, temperatures rise to several thousand degrees as a result of the arcing. Only Tungsten Copper materials will stand these high temperature & aberration.

Tungsten Copper electrical contacts have good resistance to arc erosion, mechanical wear, contact welding and good conductivity. They are usually selected for oil, gas, air or vacuum, devices. The contact surfaces will oxidize when switched in air. These press-sinter-infiltrate materials should only be considered for arcing surfaces in air when used as arcing tips, arc plates and arc runners. When switching with moderate contact arcing, the Tungsten Copper with a high copper content may give the lowest erosion. As arcing severity increases, the Tungsten Copper with the higher refractory content withstand arc erosion better. Tungsten Coppers are also used as arcing edges of selector switchblades in transformer tap changers.They excel in these applications because they withstand the effects of the arcing incident to the interruptions of large current. Tungsten has the highest strength & melting temperature of the refractory metals. This is the principal factor determining the contacts resistance to arc erosion & mechanical wear. The strength, erosion & weld characteristics of the contact increase with increasing tungsten content, however the electrical & thermal characteristics decrease with the increasing refractory content.

The high electrical and thermal conductivity of tungsten composites allows a cool, effective transfer of power, while the excellent arc-resistance properties of tungsten composites minimize arc erosion and transfer problems. These characteristics can be varied by composition—more silver or copper yields higher electrical and thermal conductivity, while a higher refractory metal content results in superior arc erosion properties. China Tungsten offers a variety of composites to meet your demands. Regardless of the environment (oil-filled devices, air and gas circuit breakers, contactors, high voltage switch gear) or the application (arcing contacts and plates, arc runners, current carrying members and blade facings), you won't be disappointed in electrical contacts made from Mi-Tech Metals' copper and silver tungsten composites.